3 Types of Concrete Pavement JPCP, JRCP & CRCP

Types of Concrete Pavement

In pavement construction, three different concrete pavement design types are commonly used:

- Jointed Plain Concrete Pavements (JPCP),

- Jointed Reinforced Concrete Pavements (JRCP), and

- Continuously Reinforced Concrete Pavements (CRCP)

Each of these design types can provide long-lasting pavements that meet or exceed specific project requirements. Each type is suitable for new construction, reconstruction, and overlays (resurfacing) of existing roads.

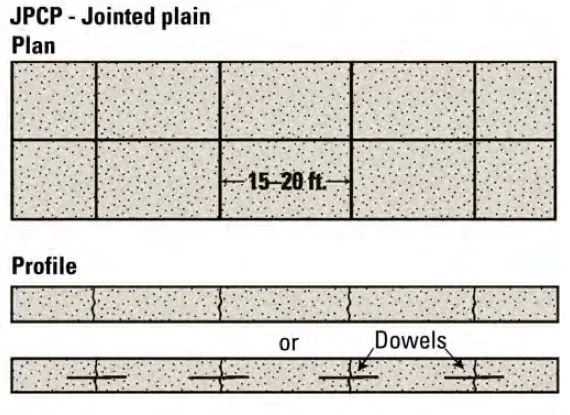

1. JPCP [Jointed Plain Concrete Pavement]

Because of their cost-effectiveness and reliability, the vast majority of concrete pavements constructed today are JPCP designs. They do not contain reinforcement. They have transverse joints generally spaced less than 5 to 6.5 m (15 to 20 ft) apart. They may contain dowel bars across the transverse joints to transfer traffic loads across slabs and may contain tie bars across longitudinal joints to promote aggregate interlock between slabs.

2. JRCP [Jointed Reinforced Concrete Pavement]

JRCP designs contain both joints and reinforcement (e.g., welded wire fabric, deformed steel bars). Joint spacings are longer (typically about 9 to 12 m [30 to 40 ft]), and dowel bars and tie bars are used at all transverse and longitudinal joints, respectively.

The reinforcement, distributed throughout the slab, composes about 0.15 to 0.25 percent of the cross-sectional area and is designed to hold tightly together any transverse cracks that develop in the slab. It is difficult to ensure that joints are cut where the reinforcement has been discontinued. This pavement type is not as common as it once was on State highways, but it is used to some extent by municipalities.

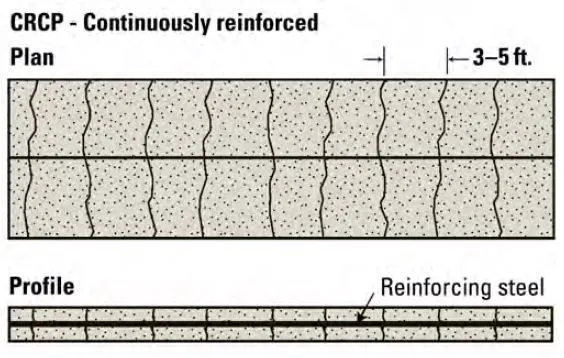

3. CRCP [Continuously Reinforced Concrete Pavement]

CRCP designs have no transverse joints, but contain a significant amount of longitudinal reinforcement, typically 0.6 to 0.8 percent of the cross-sectional area. Transverse reinforcement is often used. The high content of reinforcement both influences the development of transverse cracks within an acceptable spacing (about 0.9 to 2.5 m [3 to 8 ft] apart) and serves to hold cracks tightly together. Some agencies use CRCP designs for high-traffic, urban routes because of their suitability for high-traffic loads.